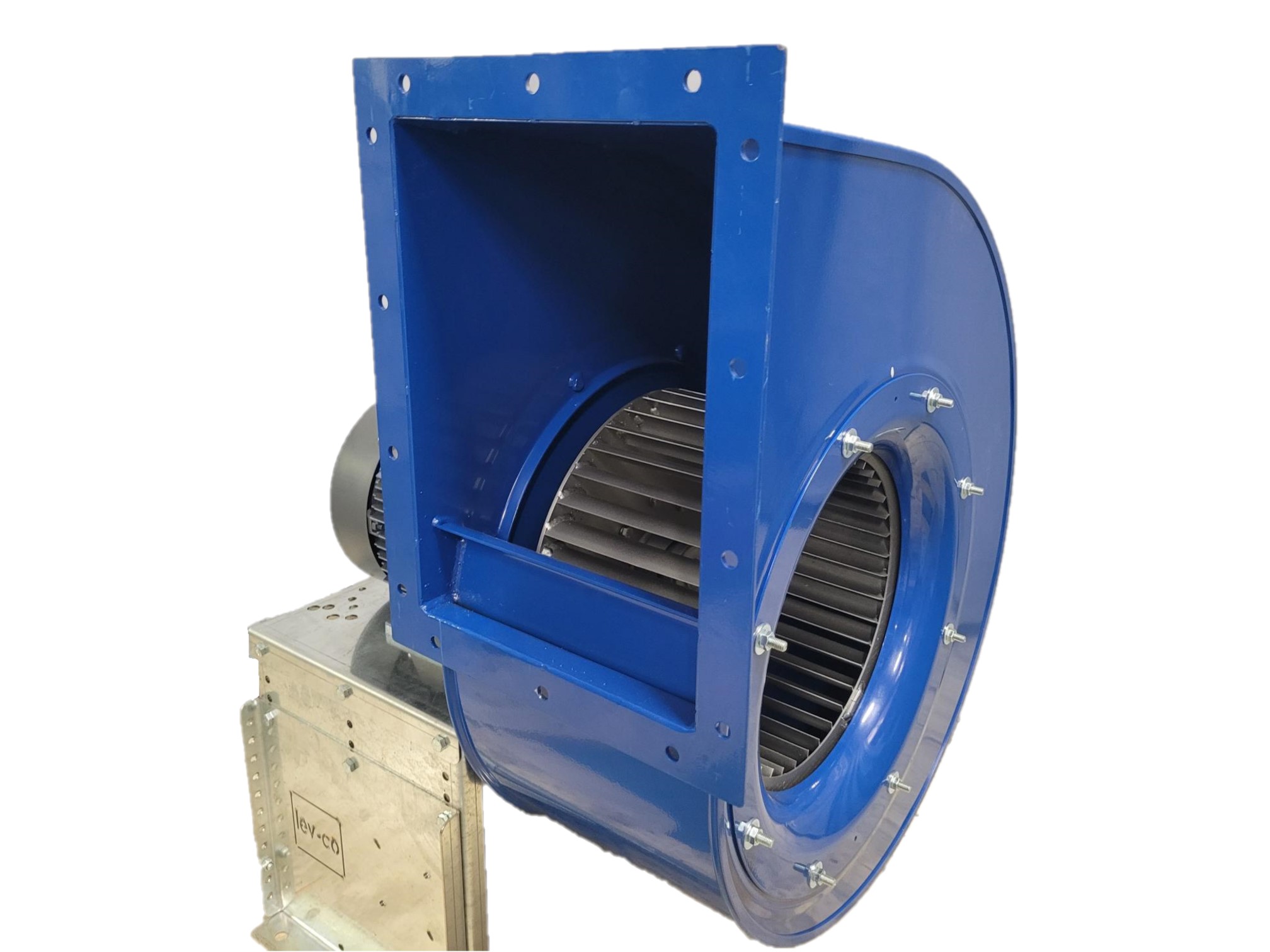

Exhaust Fans & Controls

Fans for air make up and exhaust are quite often a difficult product to find when designing a simple ducted local exhaust system.

Here we offer a variety of "LEV" (Local Exhaust and Ventilation) fans specifically designed to meet the demands of such systems.

These Fans are able to handle specific applications such as:

- Corrosive Fumes

- Abrasive Dusts

- Proper Flow and Static Pressure for a particular application.

Please feel free to contact one of our System Design Technicians for help in selecting the right fan for your application.

- Art's - Cleaning with Solvents and VOC's

- Auto body repair - Steel Welding

- Chemicals and Plastics - Resin Manufacturing

- Chemicals and Plastics - Rubber Manufacturing

- Chemicals and Plastics - Soap Manufacturing

- Construction - Concrete Demolition Hammer

- Educational - Auto Shop

- Educational - Welding Shop

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Food & Beverage - Canning

- Food & Beverage - Food Packaging Plant

- Food & Beverage - Fruit Production

- Food & Beverage - Refrigeration

- Forensics - Forensic Laboratories

- Machine Shop - Straight Line Automatic Buffing

- Marine - Hull Building

- Mining & Quarrying - Drilling

- Mining & Quarrying - Lead Smelting

- Mining & Quarrying - Nickel Mining

- Misc. Operations - Cigarette and Tobacco Smoke

- Misc. Operations - Mortuary Table

- MRO - Diesel Engines Repair

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- Painting - Dip Tank

- Painting - Drying Oven Ventilation

- Painting - Large Paint Booth

- Painting - Paint Mix Storage Room

- Painting - Trailer Interior Spray Painting

- Paper & Leather - Paper Bleaching

- Paper & Leather - Paper Pulping

- Process Engineering - Air Cooled Mixer and Muller

- Process Engineering - Banbury Mixer

- Process Engineering - Bucket Elevator Ventilation

- Process Engineering - Mixer And Muller Hood

- Process Engineering - Roller Mill Ventilation

- Public Transportation - Bus Maintenance and Repair

- Public Transportation - Subway Maintenance and Repair

- Public Transportation - Train Maintenance and Repair

- Refineries & Energy - Renewable Energy Manufacturing

- Robotics - Robot Manufacturing

- Vehicle Repair - Cars & Small Trucks Repair

- Vehicle Repair - Diesel Engines Repair

- Vehicle Repair - Truck Repair

- Waste Management - Vehicle Repair Garage

- Welding Shops - Steel Welding

- Woodworking - Wood Briquetting

- Woodworking - Wood Incineration

Yes, when correctly configured, our extraction systems will work for years without issue, and will greatly improve the air quality of your facility. We have sales engineers ready to answer your questions to ensure you get the product you need.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It is our mission to reduce that figure, but only if the right equipment is used and configured properly. As part of our comprehensive customer service, we are dedicated to making the logistics of those questions as straightforward and coherent as possible, and as such will collaborate with you to ensure the best extraction system for your workers. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO